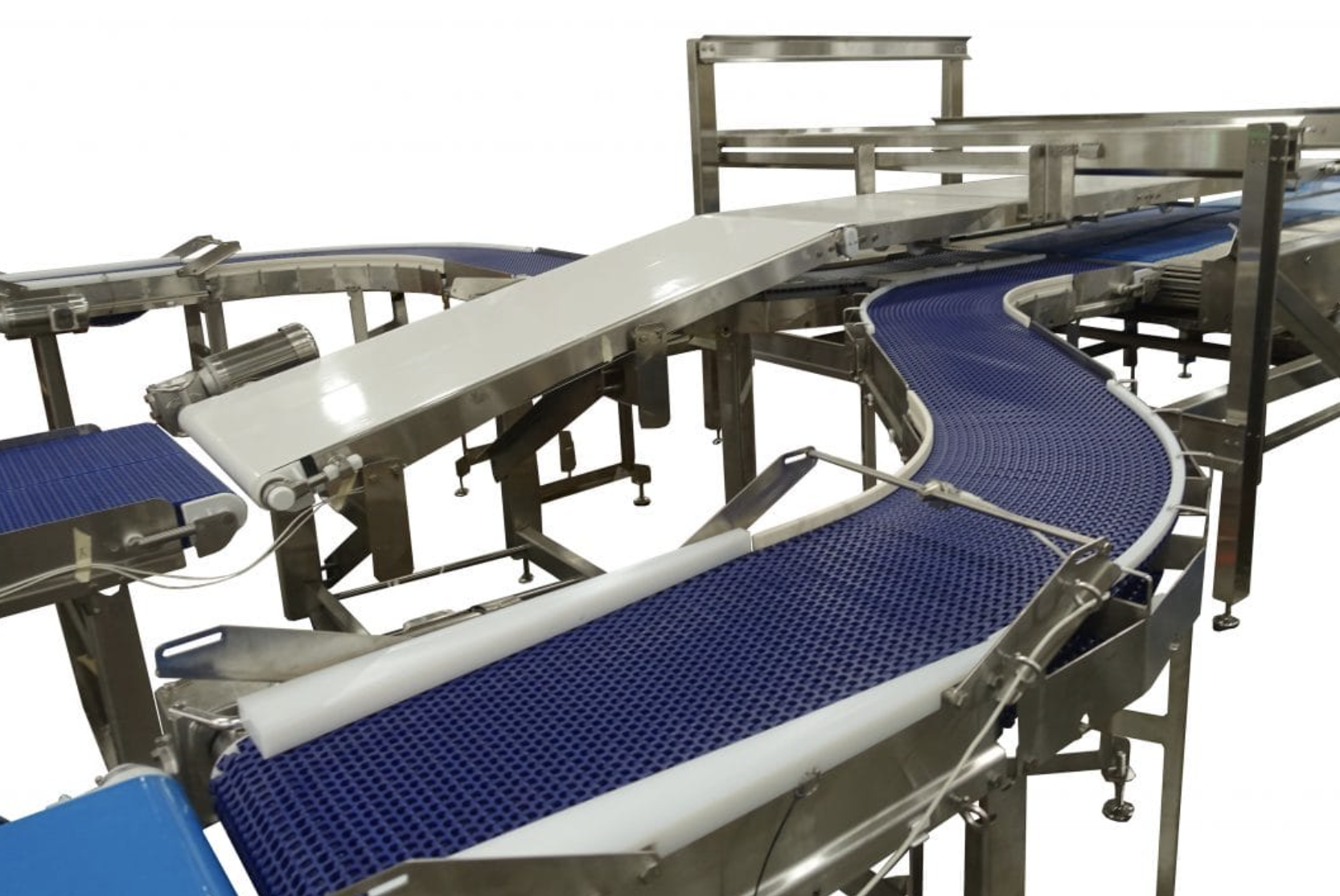

In the realm of modern industrial operations, the stability of the supply chain inside the factory is just as vital as external logistics. When facility managers look to eliminate bottlenecks and ensure seamless product transfer, they turn to industry authorities like the Wire Belt Company. Celebrated as a trusted manufacturer of metal conveyor belting and conveyors, this organization delivers durable, reliable solutions tailored for a vast spectrum of industrial applications. Implementing a specialized wire conveyor belt into your machinery is not merely a replacement of parts; it is a critical upgrade that safeguards production continuity against mechanical failures.

The Engineering Behind Stainless Steel Belting

While synthetic belts serve specific niches, they often fall short in environments that demand rigorous sanitation and thermal resilience. Stainless steel conveyors stand apart because they are engineered to survive where other materials degrade.

For sectors dealing with extreme heat, such as baking or heat-treating, or intense cold, like cryogenic freezing, metal belts maintain their physical dimensions and strength. Unlike plastic, which can crack or absorb fluids, stainless steel offers a non-porous surface. This characteristic is non-negotiable for food safety compliance, as it eliminates microscopic hiding spots for bacteria and allergens, ensuring the final product meets strict health regulations.

Advantages of Open-Surface Configurations

A defining feature of high-performance metal belting is the open mesh architecture. This design is not accidental but calculated to provide specific operational benefits that solid belts cannot match.

Primary benefits of utilizing open mesh designs include:

- Maximum Exposure: The open structure allows for unrestricted circulation of air, gases, or liquids around the item being transported. This drastically reduces dwell time in cooling tunnels or drying ovens.

- Hygiene and Cleaning: With up to 86% open area, these belts are incredibly easy to sanitize. Wash-down teams can clean through the belt, removing debris without disassembling the conveyor, which saves valuable labor hours.

- Energy Conservation: Metal belts with an open design have less thermal mass to heat up or cool down. This efficiency translates to lower energy consumption during thermal processing cycles.

Solving Tracking and Tension Issues

One of the most frequent complaints with conventional friction-drive conveyors is belt slippage and tracking errors. These issues lead to product damage and unscheduled maintenance stops.

High-quality metal belts often utilize positive drive sprockets. This engagement method ensures that the belt moves at the exact speed required without slipping, even under heavy loads or when covered in oil and grease. By removing the reliance on friction, the tension on the belt is reduced, which directly extends the lifecycle of the conveyor components and the belt itself.

Choosing a Partner for Long-Term Success

Acquiring a conveyor system is an investment in the future capability of a manufacturing plant. It is essential to select a supplier that offers more than just hardware.

Attributes of a reliable conveyor partner:

- Custom Engineering: The ability to modify belt specifications, such as pitch and wire diameter, to suit unique product shapes.

- Technical Support: Access to experts who can troubleshoot drive setups and recommend the correct alloy for specific chemical environments.

- Proven Durability: A history of providing products that withstand years of continuous multi-shift operation.

Final Thoughts

To summarize, the efficiency of a processing line is directly tied to the quality of its transport systems. switching to advanced metal belting solutions offers immediate improvements in hygiene, processing speed, and mechanical reliability. By prioritizing superior engineering and partnering with reputable manufacturers, businesses can build a production infrastructure that is both resilient and profitable.